|

|

|

|

SPOTLIGHT IN THE LAB

|

MUSC

machine

shop facilities research in regenerative medicine

What

The rapidly developing research focus at MUSC in regenerative medicine,

which offers the potential to make “replacement parts” for the human

body grown from a patient’s own cells. MUSC is fortunate to have a

Research Machine Shop Facility operated under the auspices of the

Office of the Associate Provost for Research, Stephen Lanier, Ph.D., to

assist researchers in building custom equipment needed for cutting edge

research. It also provides the capability for modification and repair

of existing equipment.

The Researcher

Bioengineering

professor Dr. Xuejun Wen, left, graduate student Van Tran, right, and

machinist Johnny Mole discuss the development of an instrument designed

to do 3D printing of the mineral scaffold for bioengineered bone. Bioengineering

professor Dr. Xuejun Wen, left, graduate student Van Tran, right, and

machinist Johnny Mole discuss the development of an instrument designed

to do 3D printing of the mineral scaffold for bioengineered bone.

Xuejun Wen, M.D., Ph.D., a member of the faculty of the Clemson-MUSC

Bioengineering Program is working to develop the capability to generate

bones. Van Tran, a Ph.D. student working with Wen, is assembling a

custom “three-dimensional printer” using parts made by the machine shop

as well as a variety of other commercially available components.

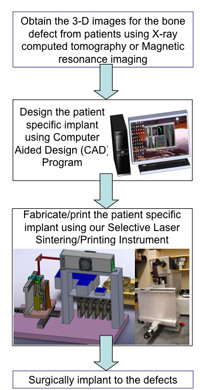

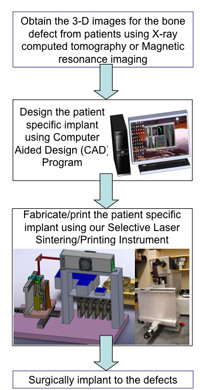

How it Works

This

instrument will generate the “mineral scaffold” for growing bones from

bone cells. A computer generated drawing of the required bone shape is

converted to a series of computer instructions for the instrument to

build the scaffold by fusing fine grains of mineral material with a

high powered laser beam focused to a very small area. This project,

typical of the area of bioengineering, weds a series of areas of

engineering, computer science, laser science, mechanics, chemistry, and

biology to produce an instrument to make bones for therapeutic uses. This

instrument will generate the “mineral scaffold” for growing bones from

bone cells. A computer generated drawing of the required bone shape is

converted to a series of computer instructions for the instrument to

build the scaffold by fusing fine grains of mineral material with a

high powered laser beam focused to a very small area. This project,

typical of the area of bioengineering, weds a series of areas of

engineering, computer science, laser science, mechanics, chemistry, and

biology to produce an instrument to make bones for therapeutic uses.

Wen, recently appointed Center of Economic Excellence Endowed Professor

of Bioengineering, said the success of any bioengineering research

program is greatly dependent on the on-campus machining and

microfabrication facility. “We are very fortunate to have a

professional machine shop on our medical school campus.”

Did you know

The Machine Shop Facility provides services in design, construction,

modification, and repair of research equipment. Capabilities include

computer- assisted design, inert gas welding and sheet metal

fabrication.

Constructed in Dan Knapp’s laboratory, the facility can provide laser

micromachining with ability to drill holes down to 10 microns.

Researchers with machine shop needs may contact Johnny Mole, machinist

(792-9077, molejj@ musc.edu) or Knapp, Ph.D. (792-5830,

knappdr@musc.edu).

Friday, Dec. 10, 2010

|

|

|

This

instrument will generate the “mineral scaffold” for growing bones from

bone cells. A computer generated drawing of the required bone shape is

converted to a series of computer instructions for the instrument to

build the scaffold by fusing fine grains of mineral material with a

high powered laser beam focused to a very small area. This project,

typical of the area of bioengineering, weds a series of areas of

engineering, computer science, laser science, mechanics, chemistry, and

biology to produce an instrument to make bones for therapeutic uses.

This

instrument will generate the “mineral scaffold” for growing bones from

bone cells. A computer generated drawing of the required bone shape is

converted to a series of computer instructions for the instrument to

build the scaffold by fusing fine grains of mineral material with a

high powered laser beam focused to a very small area. This project,

typical of the area of bioengineering, weds a series of areas of

engineering, computer science, laser science, mechanics, chemistry, and

biology to produce an instrument to make bones for therapeutic uses.